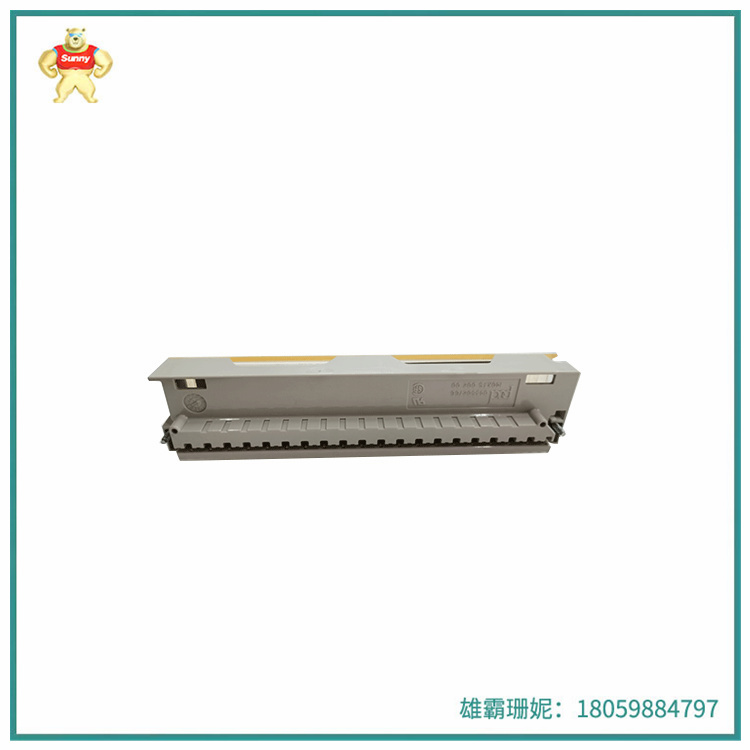

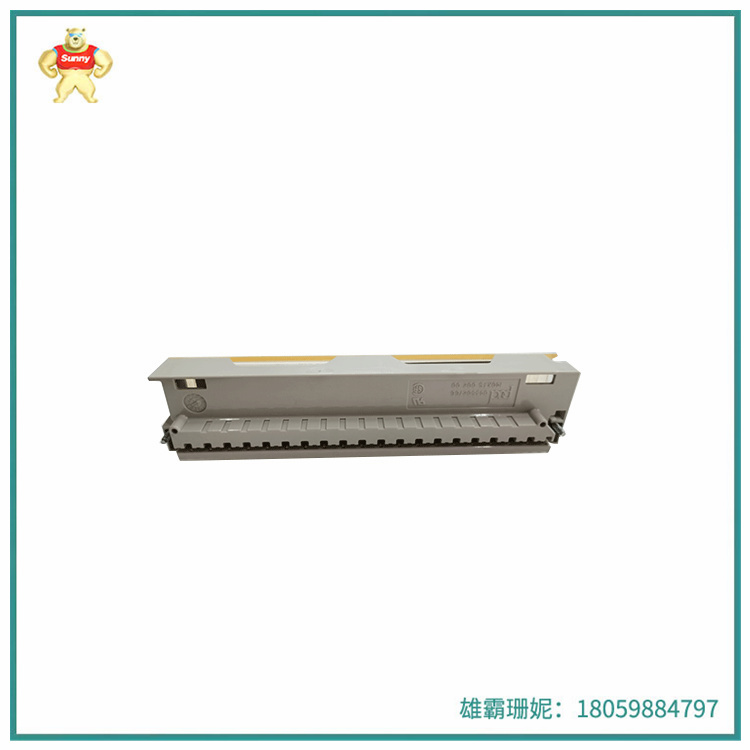

140XTS00200 螺钉接线端子

螺钉接线端子是采用螺钉式接线端子的连接方式,通过螺钉将两个带电导体连接在一起。这种连接方式需要特别注意允许连接导线的最大和最小截面以及不同规格螺钉允许的最大拧紧力矩。常见的接线端子连接方式还包括焊接和冷压端子等。在焊接中,最重要的是焊锡料与被焊接表面之间应形成金属的连续性。对于接线圆环端子,最常见的镀层是锡合金、银和金。

140XTS00200 接线端子的选择也需要考虑其材质、间距、针脚数等因素。例如,TB-I系列产品选用优化的钢夹线体结构、V0阻燃等级的外壳和优良的铜合金导流条,保证最优异的联接质量。其夹线体选用下部接口规划,顶端经过冲压构成3至4圈螺纹使螺钉旋入时充分受力,保证导线联接牢靠。此外,还需要注意产品的环保、科技、先进等方面的问题。

总之,140XTS00200 选择合适的接线端子和连接方式需要考虑多个因素,包括安全性、可靠性、经济性等。建议在选择时充分了解各种因素,并进行必要的测试和验证。

140XTS00200 螺钉式接线端子为了保证最优异的联接质量,需要采取一系列措施。首先,需要选用优质材料,如优化的钢夹线体结构、V0阻燃等级的外壳和优良的铜合金导流条等。其次,要保证夹线体和导流条的精确配合,以确保螺钉旋入时能够充分受力,使导线紧密地夹在夹线体中,避免了松动和接触不良等问题。此外,140XTS00200 螺钉式接线端子的设计也需要充分考虑导线的规格和螺钉的拧紧力矩等因素,以确保连接的可靠性和稳定性。最后,在生产过程中,还需要进行严格的质量控制和检验,确保每个接线端子的质量和性能都符合标准要求。综上所述,螺钉式接线端子通过选用优质材料、精确配合、合理设计以及严格的质量控制和检验等方面来保证最优异的联接质量。

140XTS00200 Screw terminal

The screw terminal connects two live conductors together by using the screw terminal connection method. This type of connection requires special attention to the maximum and minimum cross sections of the allowable connecting wires and the maximum tightening torques allowed for different specifications of screws. Common terminal connection methods also include welding and cord end terminals. In welding, the most important thing is that the metal continuity should be formed between the solder material and the surface to be welded. For connection ring terminals, the most common coatings are tin alloy, silver and gold.

The choice of 140XTS00200 terminal also needs to consider its material, spacing, number of pins and other factors. For example, the TB-I series products choose optimized steel clamp structure, V0 flame retardant grade housing and excellent copper alloy guide strip to ensure the best connection quality. The clamping body uses the lower interface planning, and the top is stamped to form 3 to 4 rings of thread to make the screw fully stressed to ensure the wire connection. In addition, we also need to pay attention to the environmental protection, science and technology, advanced and other aspects of the product.

In short, 140XTS00200 choose the appropriate terminal and connection method need to consider a number of factors, including safety, reliability, economy and so on. It is recommended to fully understand the various factors when choosing, and carry out the necessary testing and verification.

140XTS00200 Screw terminal In order to ensure the best connection quality, a series of measures need to be taken. First of all, it is necessary to choose high-quality materials, such as optimized steel clamp body structure, V0 flame retardant grade housing and excellent copper alloy guide strip. Secondly, it is necessary to ensure that the clip body and the guide strip are accurately matched to ensure that the screw can be fully stressed when it is screwed in, so that the wire is tightly clamped in the clip body, avoiding problems such as loosening and poor contact. In addition, the design of 140XTS00200 screw terminal also needs to fully consider the specifications of the wire and screw tightening torque and other factors to ensure the reliability and stability of the connection. Finally, in the production process, it is also necessary to carry out strict quality control and inspection to ensure that the quality and performance of each terminal meet the standard requirements. To sum up, screw terminal through the selection of high-quality materials, accurate fit, reasonable design and strict quality control and inspection to ensure the best connection quality.

Copyright © 2022-2024 厦门雄霸电子商务有限公司 版权所有 备案号:闽ICP备14012685号-33