ABB KUC720AE01 3BHB003431R0001 3BHB000652R0001 驱动模块

ABB KUC720AE01 3BHB003431R0001 3BHB000652R0001 驱动模块

PLC是采用"顺序扫描,不断循环”的方式进行工作的。即在PLC运行时,CPU根据用户按控制要求编制好并存于用户存储器中的程序,按指令步号(或地址号)作周期性循环扫描,如无跳转指令,则从条指令开始逐条顺序执行用户程序,直至程序结束。

然后重新返回条指令,开始下一轮新的扫描。在每次扫描过程中,还要完成对输入信号的采样和对输出状态的刷新等工作。PLC的一个扫描周期必经输入采样、程序执行和输出刷新三个阶段。PLC在输入采样阶段:首先以扫描方式按顺序将所有暂存在输入锁存器中的输入端子的通断状态或输入数据读入,并将写入各对应的输入状态寄存器中,即刷新输入。随即关闭输入端口,进入程序执行阶。

PLC在程序执行阶段:按用户程序指令存放的先后顺序扫描执行每条指令,经相应的运算和处理后,其结果再写入输出状态寄存器中,输出状态寄存器中所有的内容随着程序的执行而改变。输出刷新阶段:当所有指令执行完毕,输出状态寄存器的通断状态在输出刷新阶段送至输出锁存器中,并通过一定的式(继电器、晶体管或晶闸管)输出,驱动相应输出设备工作。PLC的工作过程,PLC的运行方式初研制生产的PLC主要用于代替传统的由继电器接触器构成的控制装置,但这两者的运行方式是不相同的:

(1)继电器控制装置采用硬逻辑并行运行的方式,即如果这个继电器的线圈通电或断电,该继电器所有的触点(包括其常开或常闭触点)在继电器控制线路的哪个位置上都会立即同时动作。

(2)PLC的CPU则采用顺序逻辑扫描用户程序的运行方式,即如果一个输出线圈或逻辑线圈被接通或断开,该线圈的所有触点(包括其常开或常闭触点)不会立即动作,必须等扫描到该触点时才会动作。

为了消除二者之间由于运行方式不同而造成的差异,考虑到继电器控制装置各类触点的动作时间一般在100ms以上,而PLC扫描用户程序的时间一般均小于100ms,因此,PLC采用了 -种不同于一般微型计 算机的运行方式扫描技术。这样在对于I/O响应要求不高的场合, PLC 与继电器控制装置的处理结果上就没有什么区别了。

ABB KUC720AE01 3BHB003431R0001 3BHB000652R0001 驱动模块

ABB KUC720AE01 3BHB003431R0001 3BHB000652R0001 Driver module

PLC is the use of "sequential scanning, continuous cycle" way to work. That is, when the PLC is running, the CPU is prepared according to the user's control requirements and exists in the user's memory program, according to the instruction step number (or address number) for periodic cycle scanning, if there is no jump instruction, the user program is executed successively from the beginning of the instruction until the end of the program.

Then return the bar command to start the next round of new scanning. In the process of each scan, it is necessary to complete the sampling of the input signal and refresh the output state. A PLC scan cycle must be input sampling, program execution and output refresh three stages. In the input sampling stage, PLC first reads the on-off status or input data of all the input terminals that temporarily exist in the input latch in order by scanning, and writes them into the corresponding input status register, that is, refresh the input. Then close the input port, enter the program execution level.

PLC in the program execution stage: scan and execute each instruction according to the sequence of user program instructions stored, after the corresponding operation and processing, the result is written into the output status register, and all the contents of the output status register change with the execution of the program. Output refresh stage: When all instructions are executed, the on-off state of the output status register is sent to the output latches in the output refresh stage, and is output through a certain formula (relay, transistor or thyristor) to drive the corresponding output device to work. The PLC initially developed and produced is mainly used to replace the traditional control device composed of relay contactors, but the operation mode of the two is not the same:

(1) The relay control device uses a hard logic to run in parallel, that is, if the coil of the relay is powered on or off, all the contacts of the relay (including its normally open or normally closed contacts) will immediately and simultaneously operate on the position of the relay control line.

(2) The CPU of the PLC adopts the operation mode of sequential logic scanning the user program, that is, if an output coil or logic coil is switched on or disconnected, all the contacts of the coil (including its normally open or normally closed contacts) will not act immediately, and must wait until the contact is scanned.

In order to eliminate the differences caused by different modes of operation between the two, considering that the action time of various types of contacts of the relay control device is generally more than 100ms, and the time of PLC scanning user programs is generally less than 100ms, so the PLC adopts a scanning technology that is different from the general micro computer. In this way, in the case of low I/O response requirements, there is no difference in the processing results of PLC and relay control devices.

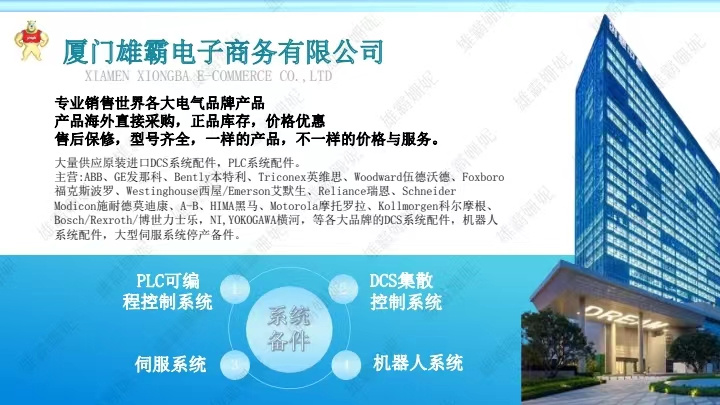

Copyright © 2022-2024 厦门雄霸电子商务有限公司 版权所有 备案号:闽ICP备14012685号-33