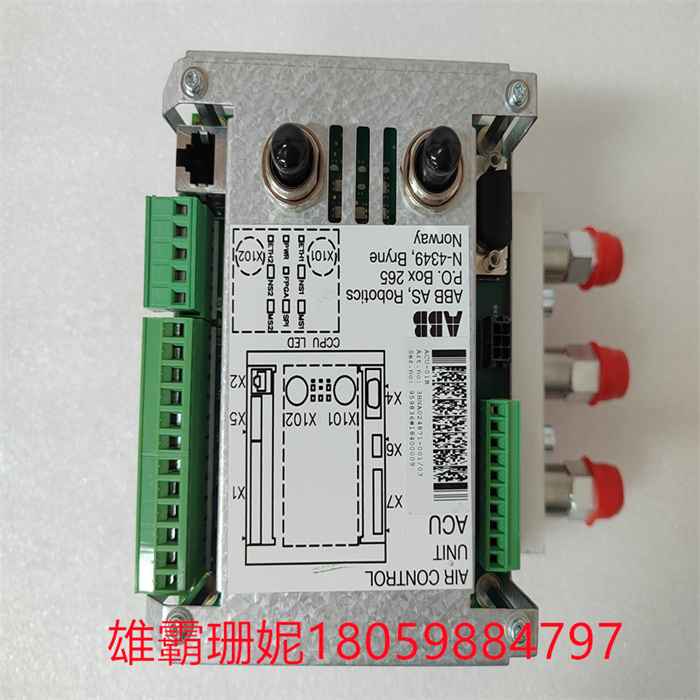

ABB ACU-01B 3HNA024871-001/03工控DCS系统模块

系统的软件设计根据硬件结构的总体划分,也可以分为两大部分来描述。整个系统的运行如图2所示,FPGA和DSP各自的程序独立运行,通过中断信号完成数据的实时交互。FPGA向DSP方向的指令是通过FPGA发送一个EDMA请求,DSP通过响应EDMA请求,建立EDMA通道,开始从FIFO中进行预处理后数据的读取,DSP向FPGA传输数据时,通过向FPGA发送一个中断信号,让其从FIFO中把压缩后的图像数据读出来。

整个系统工作流程可以简单描述如下:系统上电后,首先DSP由flash实现自举,并运行引导程序,之后转入EDMA等待状态,FPGA初始化后等待外部图像采集命令,收到图像采集命令后开始进行图像采集,并对采集到的图像进行预处理,预处理后的图像经过FIFO缓冲,在存储一定量的数据之后,FPGA通过半满信号向DSP发送EDMA请求,等待DSP响应,DSP一旦收到来自FPGA的EDMA请求,立即建立EDMA通道,从FIFO中读取数据到L2存储器,存满一帧图像后DSP开始图像压缩,等待一幅图像压缩完成之后,DSP会向FPGA发送中断信号,FPGA在收到中断信号后开始从 FIFO中读取压缩后的图像数据。一帧数据读完后,判断编码信号是否有效,如果有效则按同样的规则对下一帧图像进行压缩,如果无效则通知DSP结束。

ABB ACU-01B 3HNA024871-001/03工控DCS系统模块

为了使工业二氧化碳排放的捕获、运输和储存更容易获得,ABB 与该市场工程解决方案的 Pace CCS 签署了合作协议。

两家公司将共同运用各自的 知识,通过降低进入该市场所需的资本支出和运营投资,使工业公司更容易实施 CCS 基础设施。

CCS 涉及捕获二氧化碳 (CO 2) 工业过程中的排放物,然后通过船舶或管道将这些排放物从生产地运输到地下储存。根据麦肯锡公司的分析,各国要实现净零排放承诺,到 2050 年行业的吸收率需要增长 120 倍。如果成功,仅 CCS 一项就可以将工业部门产生的碳排放量减少 45%。

Pace CCS 执行官 Matt Healey 表示:“迄今为止,主流采用 CCS 面临的挑战之一是缺乏整个价值链的运营实践,但 ABB 和 Pace CCS 的综合 知识可以改变这一点。” “虽然公司可以看到 CCS 的好处,但如果不清楚在过程的每个阶段实际情况,他们仍然不愿意进行投资。”

ABB 和 Pace CCS 的合作伙伴关系将通过使用数字孪生技术来解决这个问题,该技术提供真实物理过程或设施的虚拟副本。该技术模拟设计阶段和测试场景以提供概念证明以确保设计符合目的。这将向客户展示他们顺利过渡到 CCS 运营。该解决方案将绘制出各种场景,包括地下建模,并将结合 ABB Ability™ OPTIMAX® 能源管理系统来预测和管理功耗。

“碳捕获和储存是加速 脱碳议程的关键组成部分。虽然我们将新的可再生能源纳入其中,但我们仍需要使用传统的能源基础设施,”ABB 能源工业总裁布兰登·斯宾塞 (Brandon Spencer) 说。“我们需要让这些更可持续,限度地减少排放,这可以通过将它们产生的二氧化碳从大气中转移到地下进行储存来实现。”

ABB ACU-01B 3HNA024871-001/03工控DCS系统模块

According to the overall division of hardware structure, the software design of the system can also be described in two parts. The operation of the whole system is shown in Figure 2. The programs of FPGA and DSP run independently, and the real-time interaction of data is completed through interrupt signals. The instruction from FPGA to DSP is to send an EDMA request through FPGA. DSP responds to the EDMA request, establishes an EDMA channel, and starts to read the preprocessed data from FIFO. When DSP transmits data to FPGA, it sends an interrupt signal to let it read the compressed image data from FIFO.

The workflow of the whole system can be simply described as follows: after the system is powered on, first, the DSP is bootstrapped by flash, and the boot program is run, and then it turns to the EDMA waiting state. After the FPGA is initialized, it waits for the external image acquisition command, and after receiving the image acquisition command, it starts to acquire the image, and preprocesses the acquired image. The preprocessed image is buffered by FIFO, and after storing a certain amount of data, The FPGA sends an EDMA request to the DSP through a half-full signal, waiting for the DSP to respond. Once the DSP receives the EDMA request from the FPGA, it immediately establishes an EDMA channel, reads data from the FIFO into the L2 memory, and starts image compression after a frame of image is filled. After an image compression is completed, the DSP sends an interrupt signal to the FPGA, and the FPGA starts reading the compressed image data from the FIFO after receiving the interrupt signal. After reading a frame of data, it is judged whether the coded signal is valid. If it is valid, the next frame of image is compressed according to the same rules. If it is invalid, it is notified to DSP to end.

ABB ACU-01B 3HNA024871-001/03工控DCS系统模块

In order to make the capture, transportation and storage of industrial carbon dioxide emissions easier, ABB signed a cooperation agreement with Pace CCS, a market engineering solution.

The two companies will jointly use their knowledge to make it easier for industrial companies to implement CCS infrastructure by reducing the capital expenditure and operating investment required to enter the market.

CCS involves capturing carbon dioxide (CO 2) emissions from industrial processes, and then transporting these emissions from the production site to underground storage through ships or pipelines. According to the analysis of McKinsey & Company, in order to realize the net zero emission commitment, the absorption rate of the industry needs to increase by 120 times by 2050. If successful, CCS alone can reduce the carbon emissions generated by the industrial sector by 45%.

Matt Healey, CEO of Pace CCS, said: "So far, one of the challenges faced by mainstream CCS adoption is the lack of operational practices throughout the value chain, but the comprehensive knowledge of ABB and Pace CCS can change this." "Although companies can see the benefits of CCS, they are still reluctant to invest if they don't know the actual situation at each stage of the process."

The partnership between ABB and Pace CCS will solve this problem by using digital twinning technology, which provides virtual copies of real physical processes or facilities. This technology simulates the design stage and test scenario to provide proof of concept to ensure that the design meets the purpose. This will show customers their smooth transition to CCS operation. The solution will draw various scenarios, including underground modeling, and will combine Abbability Optimax energy management system to predict and manage power consumption.

"Carbon capture and storage is a key component of the accelerated decarbonization agenda. Although we include new renewable energy, we still need to use traditional energy infrastructure, "said Brandon Spencer, president of ABB Energy Industry. "We need to make these more sustainable and minimize emissions, which can be achieved by transferring the carbon dioxide they produce from the atmosphere to the underground for storage."

Copyright © 2022-2024 厦门雄霸电子商务有限公司 版权所有 备案号:闽ICP备14012685号-33