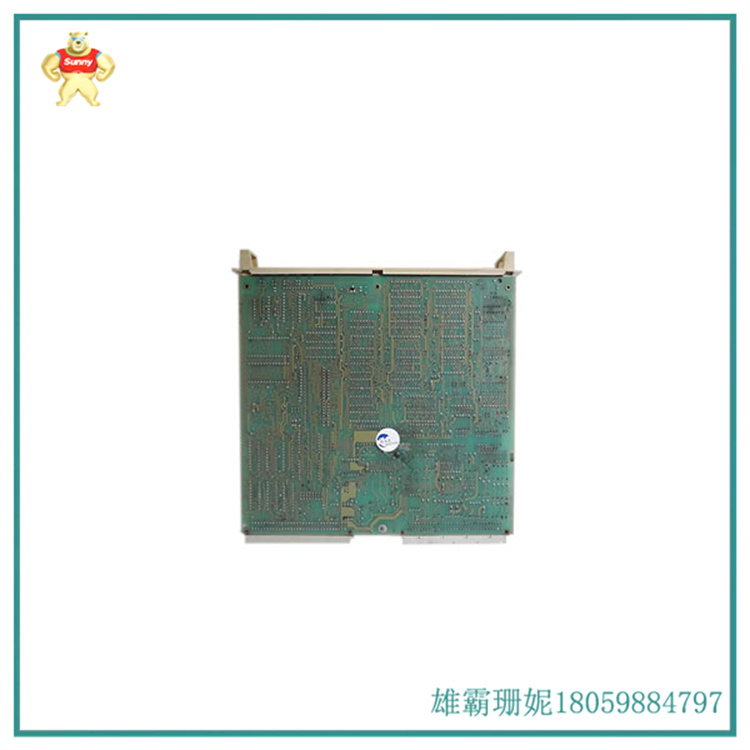

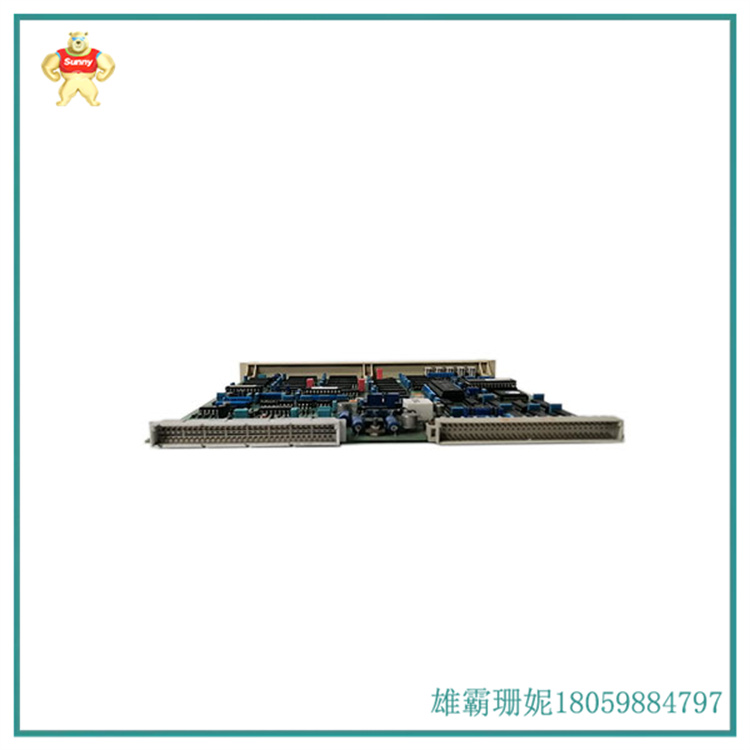

DSDP140B通过通讯模板DSDP140B把剪子启动信号t、剪剪运动位置等 控制参数通讯给DCV700系统来控制电机,电机轴上有一个增量型编码器用于剪刃位置反馈。控制系统通过定位模板DSDP140B检测电机位置编码器的实际值, -块计数模板DSDP150与DSDP140B板相连,用盱启动剪刃。定位模板DSDP140B把作用时间送到数字量输入模板DSDI110参与控制。PLC通过元素POSR_ H1 (读定位模板DSDP140B)来读取编码器所检测的剪子实际位置,而后通过POSW_ H1 (写定位模板DSDP140B)形成数据库与传动通讯,如果现场检测元件检测到钢材时,通过操作站所设定的速度基准来进行长度积分DSDP140B

DSDP140B communicates control parameters such as the scissors start signal t and the shear motion position to the DCV700 system through the communication template DSDP140B to control the motor. There is an incremental encoder on the motor shaft for blade position feedback. The control system detects the actual value of the motor position encoder through the positioning template DSDP140B, and a counting template DSDP150 is connected to the DSDP140B board to activate the cutting edge. The positioning template DSDP140B sends the action time to the digital input template DSDI110 for control. PLC through element POSR_ H1 (read positioning template DSDP140B) to read the actual position of the scissors detected by the encoder, and then use POSW_ H1 (write positioning template DSDP140B) forms a database and communicates with the transmission. If the on-site detection element detects steel, the length integration is performed using the speed reference set by the operation station

Copyright © 2022-2024 厦门雄霸电子商务有限公司 版权所有 备案号:闽ICP备14012685号-33